Solve the problem of cutting and discharging of pocket hole reamer and realize high dimensional accuracy

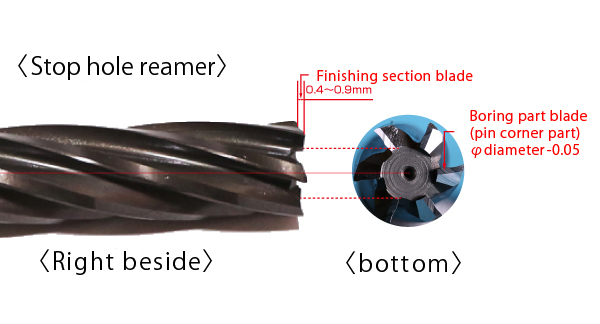

●The right spiral discharges the chips backwards, and there is no chance to remove chips in the bottom of the hole.

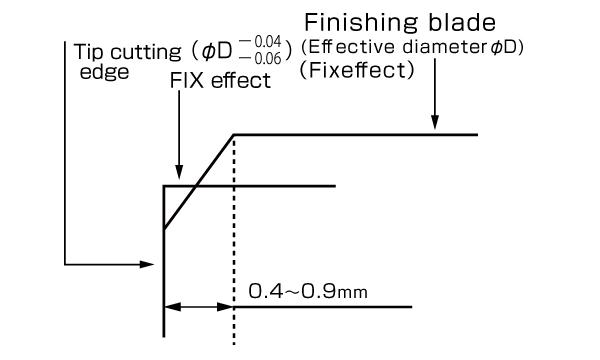

●Because it has a bottom blade, fading is possible and it is all effective diameter except for the tip IC.

●The dual structure of boring blade (FIX effect) and finishing blade makes it possible to obtain high dimensional accuracy and excellent surface roughness without reamer removal as a problem.

●It uses high-grade high-speed (including cobalt) as a reamer material, and it is more excellent in durability by ionic nitrogenization.

Characteristic

Features of stop hole reamer (pocket hole reamer)

Bladder hole reamer processing was a problem with discharge of cutting with a straight blade, the instability of dimensional precision and difficult problems with the right spiral blade, but our Flat hole reamer has developed a unique structure for those problems solved.

When using

・Please carry out chamfering work of pilot hole as preprocessing.

・Please pay attention to reel core runout, misalignment and fix the work tightly.

・Please use high quality water insoluble cutting oil.

Cutting conditions

- 1.For general steels, please choose cutting speed 10 ~ 15 m / min, feed speed 0.1 ~ 0.2 mm / rev, reamer fee 0.3-0.5 mm in diameter.

- 2.For difficult-to-cut materials, please set the cutting speed to 5 to 7 m / min.

- 3. For non-metals, please set the cutting speed to 15 ~ 20 m / min.

standard

Stop hole reamer MT axis Specification

| OD | tolerance | Blade length | shank

Lower length |

full length | shank | Number of blades

(Boring / cutting edge) |

|---|---|---|---|---|---|---|

| 5.0 | +0.006 +0.003 |

30 | 44.5 | 110 | MT1 | 4(2+2) |

| 5.5 | 〃 | 30 | 44.5 | 110 | MT1 | 4(2+2) |

| 6.0 | 〃 | 30 | 44.5 | 110 | MT1 | 4(2+2) |

| 6.5 | 〃 | 40 | 54.5 | 120 | MT1 | 4(2+2) |

| 7.0 | +0.008 +0.004 |

40 | 54.5 | 120 | MT1 | 4(2+2) |

| 7.5 | 〃 | 40 | 54.5 | 120 | MT1 | 4(2+2) |

| 8.0 | 〃 | 40 | 54+.5 | 120 | MT1 | 4(2+2) |

| 8.5 | 〃 | 50 | 69.5 | 135 | MT1 | 4(2+2) |

| 9.0 | 〃 | 50 | 69.5 | 135 | MT1 | 4(2+2) |

| 9.5 | 〃 | 50 | 69.5 | 135 | MT1 | 4(2+2) |

| 10.0 | 〃 | 50 | 69.5 | 135 | MT1 | 6(3+3) |

| 10.5 | 〃 | 60 | 79.5 | 145 | MT1 | 6(3+3) |

| 11.0 | +0.009 +0.004 |

60 | 79.5 | 145 | MT1 | 6(3+3) |

| 11.5 | 〃 | 60 | 79.5 | 145 | MT1 | 6(3+3) |

| 12.0 | 〃 | 60 | 79.5 | 145 | MT1 | 6(3+3) |

| 12.5 | 〃 | 70 | 89.5 | 155 | MT1 | 6(3+3) |

| 13.0 | 〃 | 70 | 89.5 | 155 | MT1 | 6(3+3) |

| 13.5 | 〃 | 70 | 89.5 | 155 | MT1 | 6(3+3) |

| 14.0 | +0.009 +0.004 |

70 | 89.5 | 155 | MT1 | 6(3+3) |

| 14.5 | 〃 | 70 | 89.5 | 155 | MT1 | 6(3+3) |

| 15.0 | 〃 | 90 | 110 | 190 | MT2 | 6(3+3) |

| 15.5 | 〃 | 90 | 110 | 190 | MT2 | 6(3+3) |

| 16.0 | 〃 | 90 | 110 | 190 | MT2 | 6(3+3) |

| 16.5 | 〃 | 100 | 120 | 200 | MT2 | 6(3+3) |

| 17.0 | 〃 | 100 | 120 | 200 | MT2 | 6(3+3) |

| 17.5 | 〃 | 100 | 120 | 200 | MT2 | 6(3+3) |

| 18.0 | +0.011 +0.006 |

100 | 120 | 200 | MT2 | 6(3+3) |

| 18.5 | 〃 | 100 | 120 | 200 | MT2 | 6(3+3) |

| OD | tolerance | Blade length | shank

Lower length |

full length | shank | Number of blades

(Boring / cutting edge) |

|---|---|---|---|---|---|---|

| 19.0 | +0.011 +0.006 |

100 | 120 | 200 | MT2 | 6(3+3) |

| 19.5 | 〃 | 100 | 120 | 200 | MT2 | 6(3+3) |

| 20.0 | 〃 | 100 | 120 | 200 | MT2 | 6(3+3) |

| 20.5 | +0.011 +0.006 |

100 | 130 | 210 | MT2 | 6(3+3) |

| 21.0 | 〃 | 110 | 130 | 210 | MT2 | 6(3+3) |

| 21.5 | 〃 | 120 | 140 | 220 | MT2 | 6(3+3) |

| 22.0 | 〃 | 120 | 140 | 220 | MT2 | 6(3+3) |

| 22.5 | 〃 | 120 | 140 | 220 | MT2 | 6(3+3) |

| 23.0 | 〃 | 120 | 140 | 220 | MT2 | 6(3+3) |

| 23.5 | 〃 | 120 | 140 | 220 | MT2 | 6(3+3) |

| 24.0 | 〃 | 130 | 151 | 250 | MT3 | 8(4+4) |

| 24.5 | 〃 | 130 | 151 | 250 | MT3 | 8(4+4) |

| 25.0 | 〃 | 130 | 151 | 250 | MT3 | 8(4+4) |

| 25.5 | 〃 | 130 | 151 | 250 | MT3 | 8(4+4) |

| 26.0 | 〃 | 130 | 151 | 250 | MT3 | 8(4+4) |

| 26.5 | 〃 | 140 | 161 | 260 | MT3 | 8(4+4) |

| 27.0 | 〃 | 140 | 161 | 260 | MT3 | 8(4+4) |

| 27.5 | 〃 | 140 | 161 | 260 | MT3 | 8(4+4) |

| 28.0 | 〃 | 140 | 161 | 260 | MT3 | 8(4+4) |

| 28.5 | 〃 | 140 | 161 | 250 | MT3 | 8(4+4) |

| 29.0 | 〃 | 140 | 161 | 260 | MT3 | 8(4+4) |

| 29.5 | 〃 | 140 | 161 | 260 | MT3 | 8(4+4) |

| 29.0 | 〃 | 140 | 161 | 260 | MT3 | 8(4+4) |

| 30.0 | 〃 | 140 | 161 | 260 | MT3 | 8(4+4) |

| 30.5 | 〃 | 150 | 171 | 270 | MT3 | 8(4+4) |

| 31.0 | 〃 | 150 | 171 | 270 | MT3 | 8(4+4) |

| 31.5 | 〃 | 150 | 171 | 270 | MT3 | 8(4+4) |

| 32.0 | 〃 | 150 | 171 | 270 | MT3 | 8(4+4) |

Stop hole reamer S axis Specification

[4 mm to 20 mm - 0.1 mm jump standard item], [4 mm to 30 mm - 0.5 mm jump standard item]

| OD | tolerance | Blade length | full length | Shank diameter | Shank length | Number of blades

(Boring / cutting edge) |

|---|---|---|---|---|---|---|

| 3.0 | +0.006 +0.003 |

30 | 70 | 6.0 | 30 | 4(2+2) |

| 3.5 | 〃 | 30 | 70 | 6.0 | 30 | 4(2+2) |

| 4.0 | 〃 | 30 | 75 | 6.0 | 30 | 4(2+2) |

| 4.5 | 〃 | 30 | 75 | 6.0 | 30 | 4(2+2) |

| 5.0 | 〃 | 30 | 75 | 6.0 | 30 | 4(2+2) |

| 6.0 | 〃 | 30 | 75 | 6.0 | 30 | 4(2+2) |

| 6.5 | 〃 | 40 | 90 | 8.0 | 35 | 4(2+2) |

| 7.0 | +0.008 +0.004 |

40 | 90 | 8.0 | 35 | 4(2+2) |

| 7.5 | 〃 | 40 | 90 | 8.0 | 35 | 4(2+2) |

| 8.0 | 〃 | 40 | 90 | 8.0 | 35 | 4(2+2) |

| 8.5 | 〃 | 50 | 105 | 10.0 | 40 | 4(2+2) |

| 9.0 | 〃 | 50 | 105 | 10.0 | 40 | 4(2+2) |

| 9.5 | 〃 | 50 | 105 | 10.0 | 40 | 4(2+2) |

| 10.0 | 〃 | 50 | 105 | 10.0 | 40 | 6(3+3) |

| 10.5 | 〃 | 60 | 125 | 12.0 | 45 | 6(3+3) |

| 11.0 | +0.009 +0.004 |

60 | 125 | 12.0 | 45 | 6(3+3) |

| 11.5 | 〃 | 60 | 125 | 12.0 | 45 | 6(3+3) |

| 12.0 | 〃 | 60 | 125 | 12.0 | 45 | 6(3+3) |

| 12.5 | 〃 | 70 | 140 | 12.0 | 50 | 6(3+3) |

| 13.0 | 〃 | 70 | 140 | 12.0 | 50 | 6(3+3) |

| 13.5 | 〃 | 70 | 140 | 12.0 | 50 | 6(3+3) |

| 14.0 | 〃 | 70 | 140 | 12.0 | 50 | 6(3+3) |

| 14.5 | 〃 | 70 | 140 | 12.0 | 50 | 6(3+3) |

| 15.0 | 〃 | 90 | 190 | 12.0 | 85 | 6(3+3) |

| 15.5 | 〃 | 90 | 190 | 12.0 | 85 | 6(3+3) |

| 16.0 | 〃 | 90 | 190 | 16.0 | 85 | 6(3+3) |

| 16.5 | 〃 | 100 | 200 | 16.0 | 85 | 6(3+3) |

| 17.0 | 〃 | 100 | 200 | 16.0 | 85 | 6(3+3) |

| 17.5 | 〃 | 100 | 200 | 16.0 | 85 | 6(3+3) |

| 18.0 | +0.011 +0.006 |

100 | 200 | 16.0 | 85 | 6(3+3) |

| OD | tolerance | Blade length | Shank diameter | Shank length | full length | Number of blades

(Boring / cutting edge) |

|---|---|---|---|---|---|---|

| 18.5 | +0.011 +0.006 |

100 | 200 | 16.0 | 85 | 6(3+3) |

| 19.0 | 〃 | 100 | 200 | 16.0 | 85 | 6(3+3) |

| 19.5 | 〃 | 100 | 200 | 16.0 | 85 | 6(3+3) |

| 20.0 | 〃 | 100 | 200 | 20.0 | 85 | 6(3+3) |

| 20.5 | 〃 | 110 | 200 | 20.0 | 85 | 6(3+3) |

| 21.0 | 〃 | 110 | 210 | 20.0 | 85 | 6(3+3) |

| 21.5 | 〃 | 120 | 220 | 20.0 | 85 | 6(3+3) |

| 22.0 | 〃 | 120 | 220 | 20.0 | 85 | 6(3+3) |

| 22.5 | 〃 | 120 | 220 | 20.0 | 85 | 6(3+3) |

| 23.0 | 〃 | 120 | 220 | 20.0 | 85 | 6(3+3) |

| 23.5 | 〃 | 120 | 220 | 20.0 | 85 | 6(3+3) |

| 24.0 | 〃 | 130 | 250 | 20.0 | 100 | 8(4+4) |

| 24.5 | 〃 | 130 | 250 | 20.0 | 100 | 8(4+4) |

| 25.0 | 〃 | 130 | 250 | 20.0 | 100 | 8(4+4) |

| 25.5 | 〃 | 130 | 250 | 20.0 | 100 | 8(4+4) |

| 26.0 | 〃 | 130 | 250 | 20.0 | 100 | 8(4+4) |

| 26.5 | 〃 | 140 | 260 | 20.0 | 100 | 8(4+4) |

| 27.0 | 〃 | 140 | 260 | 20.0 | 100 | 8(4+4) |

| 27.5 | +0.011 +0.006 |

140 | 260 | 25.0 | 100 | 8(4+4) |

| 28.0 | 〃 | 140 | 260 | 25.0 | 100 | 8(4+4) |

| 28.5 | 〃 | 140 | 260 | 25.0 | 100 | 8(4+4) |

| 29.0 | 〃 | 140 | 260 | 25.0 | 100 | 8(4+4) |

| 29.5 | 〃 | 140 | 260 | 25.0 | 100 | 8(4+4) |

| 30.0 | 〃 | 140 | 260 | 25.0 | 100 | 8(4+4) |

| 30.5 | 〃 | 150 | 270 | 25.0 | 100 | 8(4+4) |

| 31.0 | 〃 | 150 | 270 | 25.0 | 100 | 8(4+4) |

| 31.5 | 〃 | 150 | 270 | 25.0 | 100 | 8(4+4) |

| 32.0 | 〃 | 150 | 270 | 25.0 | 100 | 8(4+4) |

Please purchase the product at a machine tool trading company