All cemented carbide · ultrafine particles

●All cemented carbide · ultrafine particles

●For blind holes, for through holes, for stepped use

※TiCN coding also has various stocks

Characteristic

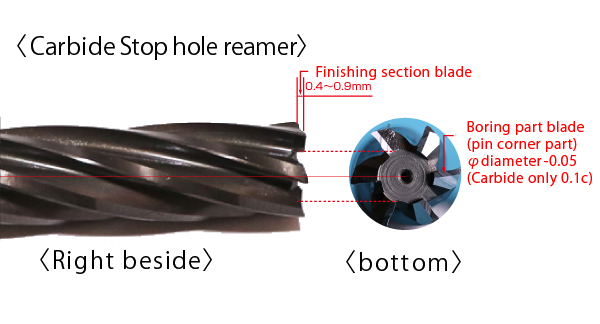

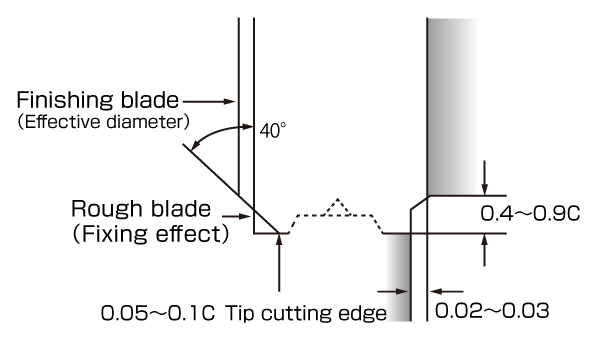

Characteristics of carbide stop hole reamer cutting mechanism

Surface accuracy is good. Our unique two-stage cutting method (rough blade, finishing blade)

It is straightforward. It is made short overall and excellent in rigidity.

Stepped processing is also possible, with bottom blade.

When using

・Please carry out chamfering work of pilot hole as preprocessing.

・Please pay attention to reel core runout, misalignment.

・Please use oil cutting oil for cutting oil.

Cutting condition reference

| Fork material | Cutting speed

m/min |

Feed

min/rev |

|---|---|---|

| steel | 12〜20 |

0.1〜0.3 |

| Tempering material | 6〜12 |

0.05〜0.2 |

| cast iron | 6〜15 |

0.1〜0.2 |

| Die steel | 6〜10 |

0.07〜0.2 |

| Stainless steel | 8〜12 |

0.1〜0.3 |

| Aluminum alloy | 20〜30 |

0.2〜0.4 |

standard

Carbide stop hole reamer Specification

| OD | Blade length | Under the neck | Shank diameter | Shank length | full length | Number of blades

(Boring / cutting edge) |

|---|---|---|---|---|---|---|

| 3.0 | 20 | 35 | 3 | 25 | 60 | 4(2+2) |

| 3.1 | 20 | 35 | 3 | 25 | 60 | 4(2+2) |

| 3.2 | 20 | 35 | 3 | 25 | 60 | 4(2+2) |

| 3.3 | 20 | 35 | 3 | 25 | 60 | 4(2+2) |

| 3.4 | 20 | 35 | 3 | 25 | 60 | 4(2+2) |

| 3.5 | 20 | 35 | 3 | 25 | 60 | 4(2+2) |

| 3.6 | 25 | 40 | 4 | 30 | 70 | 4(2+2) |

| 3.7 | 25 | 40 | 4 | 30 | 70 | 4(2+2) |

| 3.8 | 25 | 40 | 4 | 30 | 70 | 4(2+2) |

| 3.9 | 25 | 40 | 4 | 30 | 70 | 4(2+2) |

| 4.0 | 25 | 40 | 4 | 30 | 70 | 4(2+2) |

| 4.1 | 25 | 40 | 4 | 30 | 70 | 4(2+2) |

| 4.2 | 25 | 40 | 4 | 30 | 70 | 4(2+2) |

| 4.3 | 25 | 40 | 4 | 30 | 70 | 4(2+2) |

| 4.4 | 25 | 40 | 4 | 30 | 70 | 4(2+2) |

| 4.5 | 25 | 40 | 4 | 30 | 70 | 4(2+2) |

| 4.6 | 30 | 45 | 5 | 30 | 75 | 4(2+2) |

| 4.7 | 30 | 45 | 5 | 30 | 75 | 4(2+2) |

| 4.8 | 30 | 45 | 5 | 30 | 75 | 4(2+2) |

| 4.9 | 30 | 45 | 5 | 30 | 75 | 4(2+2) |

| 5.0 | 30 | 45 | 5 | 30 | 75 | 4(2+2) |

| 5.1 | 30 | 45 | 5 | 30 | 75 | 4(2+2) |

| 5.2 | 30 | 45 | 5 | 30 | 75 | 4(2+2) |

| 5.3 | 30 | 45 | 5 | 30 | 75 | 4(2+2) |

| 5.4 | 30 | 45 | 5 | 30 | 75 | 4(2+2) |

| 5.5 | 30 | 45 | 5 | 30 | 75 | 4(2+2) |

| 5.6 | 30 | 45 | 6 | 30 | 75 | 4(2+2) |

| 5.7 | 30 | 45 | 6 | 30 | 75 | 4(2+2) |

| 5.8 | 30 | 45 | 6 | 30 | 75 | 4(2+2) |

| 5.9 | 30 | 45 | 6 | 30 | 75 | 4(2+2) |

| 6.0 | 30 | 45 | 6 | 30 | 75 | 4(2+2) |

| 6.1 | 30 | 45 | 6 | 30 | 75 | 4(2+2) |

| 6.2 | 30 | 45 | 6 | 30 | 75 | 4(2+2) |

| 6.3 | 30 | 45 | 6 | 30 | 75 | 4(2+2) |

| 6.4 | 30 | 45 | 6 | 30 | 75 | 4(2+2) |

| 6.5 | 30 | 45 | 6 | 30 | 75 | 4(2+2) |

| 6.6 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 6.7 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 6.8 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 6.9 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 7.0 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 7.1 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 7.2 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 7.3 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 7.4 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 7.5 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 7.6 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| OD | tolerance | Blade length | shank

Lower length |

full length | shank | Number of blades

(Boring / cutting edge) |

|---|---|---|---|---|---|---|

| 7.7 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 7.8 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 7.9 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 8.0 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 8.1 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 8.2 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 8.3 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 8.4 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 8.5 | 40 | 55 | 8 | 35 | 90 | 4(2+2) |

| 8.6 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 8.7 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 8.8 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 8.9 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 9.0 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 9.1 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 9.2 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 9.3 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 9.4 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 9.5 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 10.0 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 10.1 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 10.2 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 10.3 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 10.4 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 10.5 | 50 | 65 | 10 | 40 | 105 | 6(3+3) |

| 10.6 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 10.7 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 10.8 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 10.9 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 11.0 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 11.2 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 11.3 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 11.4 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 11.5 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 11.6 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 11.7 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 11.8 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 11.9 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| 12.0 | 65 | 80 | 12 | 45 | 125 | 6(3+3) |

| tolerance | Non-coat | TiCN coating |

|---|---|---|

| φ3〜φ6.5 | +0.006 +0.003 |

+0.009 +0.005 |

| φ6.6〜φ10.5 | +0.008 +0.004 |

+0.010 +0.005 |

| φ10.6〜φ12.0 | +0.009 +0.004 |

+0.012 +0.005 |

Please purchase the product at a machine tool trading company