Excellent accuracy in stainless steel

●Surface roughness 6S or more with H7 accuracy is obtained

●Easy pilot hole processing

Characteristic

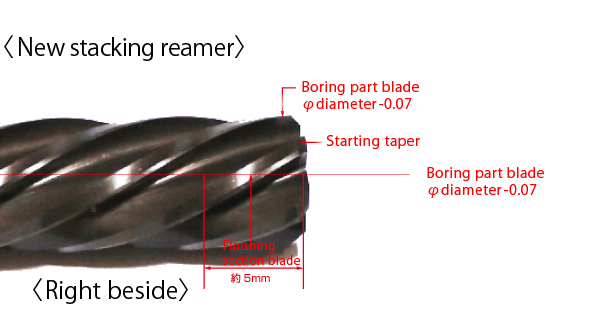

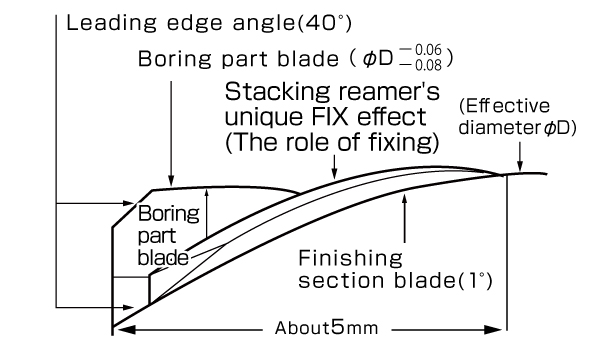

Characteristics of stacking reamer cutting mechanism

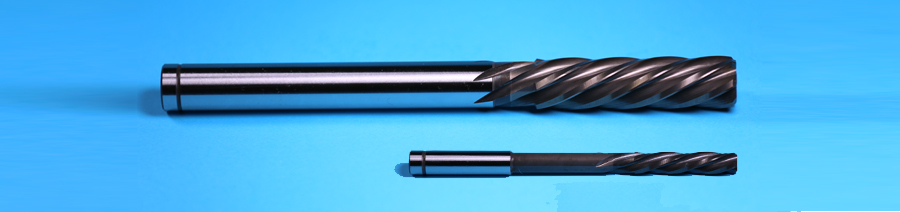

With the corner cutting edge and the boring part blade, after finishing the finish to the appropriate finish, the finishing part blade is cut to obtain high surface roughness and high precision dimensions. The boring part blade of the stacking reamer cuts the cutting resistance as a biting angle (40 °) and cuts irrespective of the size of Reamershi by our unique FIX effect. We will make Chatter small and finish it with high precision at the rake angle and the finish part of the strong left twist which took off the lesser reamashiro.

■Cutting oil

Water-soluble cutting oil is excellent in dimensional accuracy and surface roughness by minimizing the expansion amount. Insoluble cutting oil has high lubricity, so it reduces variations in the hole system and improves reamer life. Particularly when extreme pressure oil containing chlorine and also extreme pressure additives of the sulfur type is used, dimensional accuracy, surface roughness, reamer life is improved.

■Durability

Use cobalt (Co) as a reamer material. Furthermore, Hv 1150 - 1200 high hardness layer by ion nitrogen treatment has about 2/100 mm, so it is particularly effective for alloy steel, stainless steel hardness and so on.

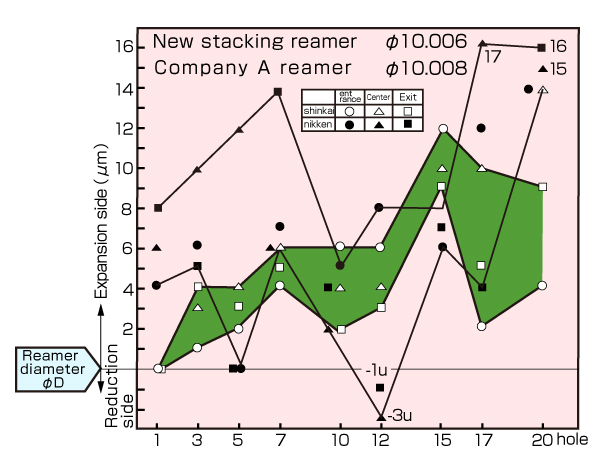

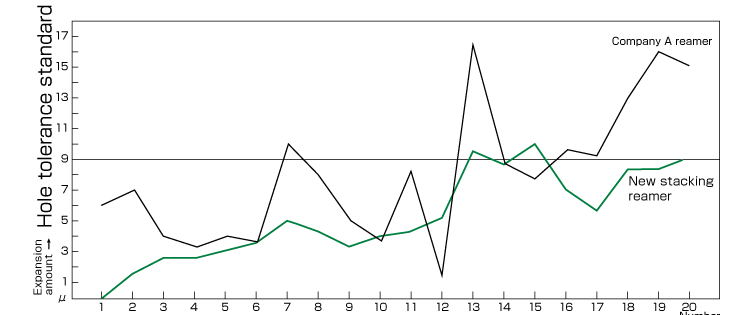

■Cylindricality, amount of expansion

Stacking reamer's original cutting structure and FIX effect of the boring part will control reamed walking phenomenon to guarantee high precision.

Cutting condition reference

Work material Reamer diameter |

General Copper SS.SC etc. | ||

|---|---|---|---|

| Cutting speed

m/min |

Feed

mm/rev |

Reamer fee

mm |

|

| 6 | 15〜8 |

0.3〜0.1 |

0.2〜0.4 |

| 12 | 15〜8 |

0.3〜0.1 |

0.2〜0.5 |

| 16 | 15〜8 |

0.3〜0.1 |

0.2〜0.5 |

| 20 | 12〜8 |

0.3〜0.1 |

0.3〜0.6 |

| 25 | 12〜8 |

0.4〜0.2 |

0.3〜0.8 |

| 30 | 12〜7 |

0.4〜0.2 |

0.3〜0.8 |

| 40 | 12〜7 |

0.4〜0.2 |

0.4〜1 |

| 50 | 15〜8 |

0.4〜0.2 |

0.4〜1 |

| Hard-to-cut material SKD.SUS etc. | ||

|---|---|---|

| Cutting speed

m/min |

Feed

mm/rev |

Reamer fee

mm |

8〜5 |

0.2〜0.1 |

0.2〜0.4 |

8〜5 |

0.2〜0.1 |

0.2〜0.4 |

8〜5 |

0.2〜0.1 |

0.3〜0.5 |

7〜4 |

0.3〜0.1 |

0.3〜0.5 |

7〜4 |

0.3〜0.1 |

0.3〜0.6 |

7〜4 |

0.3〜0.1 |

0.3〜0.6 |

7〜4 |

0.3〜0.1 |

0.3〜0.6 |

7〜4 |

0.3〜0.1 |

0.3〜0.6 |

| Nonferrous metal Aℓ.Cu alloy | ||

|---|---|---|

| Cutting speed

m/min |

Feed

mm/rev |

Reamer fee

mm |

30〜10 |

0.2〜0.1 |

0.2〜0.4 |

30〜10 |

0.3〜0.1 |

0.2〜0.5 |

30〜10 |

0.3〜0.2 |

0.3〜0.6 |

20〜10 |

0.3〜0.2 |

0.3〜0.8 |

20〜10 |

0.4〜0.2 |

0.3〜0.8 |

15〜10 |

0.4〜0.2 |

0.3〜0.8 |

15〜10 |

0.4〜0.2 |

0.4〜1 |

15〜10 |

0.4〜0.2 |

0.4〜1 |

Enlargement measurement

- Machine name used:

- Mitsui Seiki M/C VS3A(BT40)

- Cutting:

- SUS304(Sheet thickness 30mm)

- Use holder:

- BIG BT40 NBS20-90

- Cutting oil:

- Emulsion

External supply 6 coolant nozzles used - Tool used:

- I )Stacking reamer

φ10-S10

II)Company A reamer φ10-S10 - Cutting conditions:

- V=5m/min N=160rpm

F=24mm/min S=0.15mm

standard

New stacking

(Cobalt Hyth SKH 40) MT axis specification

[5 mm to 25 mm - 0.1 mm jump standard item], [5 mm to 50 mm - 0.5 mm jump standard item]

| OD | tolerance | Blade length | shank

Lower length |

full length | shank | Number of blades

(Boring / cutting edge) |

|---|---|---|---|---|---|---|

| 5.0 | +0.009 +0.004 |

30 | 54.5 | 120 | MT1 | 4(2+2) |

| 6.0 | 〃 | 30 | 62.5 | 128 | MT1 | 4(2+2) |

| 7.0 | +0.012 +0.006 |

35 | 69.5 | 135 | MT1 | 4(2+2) |

| 8.0 | 〃 | 40 | 79.5 | 145 | MT1 | 4(2+2) |

| 9.0 | 〃 | 40 | 94.5 | 160 | MT1 | 4(2+2) |

| 10.0 | 〃 | 48 | 104.5 | 170 | MT1 | 6(3+3) |

| 11.0 | +0.015 +0.007 |

51 | 109.5 | 175 | MT1 | 6(3+3) |

| 12.0 | 〃 | 54 | 119.5 | 185 | MT1 | 6(3+3) |

| 13.0 | 〃 | 54 | 119.5 | 185 | MT1 | 6(3+3) |

| 14.0 | 〃 | 57 | 124.5 | 190 | MT1 | 6(3+3) |

| 15.0 | +0.015 +0.007 |

60 | 130 | 210 | MT2 | 6(3+3) |

| 16.0 | 〃 | 60 | 130 | 210 | MT2 | 6(3+3) |

| 17.0 | 〃 | 64 | 140 | 220 | MT1 | 6(3+3) |

| 18.0 | 〃 | 68 | 140 | 220 | MT2 | 6(3+3) |

| 19.0 | +0.017 +0.008 |

68 | 140 | 220 | MT2 | 6(3+3) |

| 20.0 | 〃 | 68 | 145 | 225 | MT2 | 6(3+3) |

| 21.0 | 〃 | 70 | 150 | 230 | MT2 | 6(3+3) |

| 22.0 | 〃 | 70 | 150 | 230 | MT2 | 6(3+3) |

| 23.0 | 〃 | 70 | 160 | 240 | MT2 | 6(3+3) |

| 24.0 | 〃 | 80 | 171 | 270 | MT3 | 8(4+4) |

| 25.0 | 〃 | 80 | 171 | 270 | MT3 | 8(4+4) |

| 26.0 | 〃 | 80 | 181 | 280 | MT3 | 8(4+4) |

| 27.0 | 〃 | 80 | 181 | 280 | MT3 | 8(4+4) |

| 28.0 | 〃 | 80 | 181 | 280 | MT3 | 8(4+4) |

| 29.0 | 〃 | 80 | 181 | 280 | MT3 | 8(4+4) |

| 30.0 | 〃 | 85 | 191 | 290 | MT3 | 8(4+4) |

| 31.0 | +0.020 +0.009 |

85 | 191 | 290 | MT3 | 8(4+4) |

| 32.0 | 〃 | 90 | 201 | 300 | MT3 | 8(4+4) |

| 33.0 | 〃 | 90 | 201 | 325 | MT4 | 8(4+4) |

| 34.0 | 〃 | 90 | 201 | 325 | MT4 | 8(4+4) |

| 35.0 | 〃 | 90 | 206 | 330 | MT4 | 10(5+5) |

| 36.0 | 〃 | 90 | 206 | 330 | MT4 | 10(5+5) |

| 37.0 | 〃 | 95 | 206 | 330 | MT4 | 10(5+5) |

| OD | tolerance | Blade length | shank

Lower length |

full length | shank | Number of blades

(Boring / cutting edge) |

|---|---|---|---|---|---|---|

| 38.0 | +0.020 +0.009 |

95 | 206 | 330 | MT4 | 10(5+5) |

| 39.0 | 〃 | 95 | 206 | 330 | MT4 | 10(5+5) |

| 40.0 | 〃 | 95 | 206 | 330 | MT4 | 10(5+5) |

| 41.0 | 〃 | 95 | 206 | 330 | MT4 | 10(5+5) |

| 42.0 | 〃 | 95 | 216 | 340 | MT4 | 10(5+5) |

| 43.0 | 〃 | 95 | 216 | 340 | MT4 | 10(5+5) |

| 44.0 | 〃 | 95 | 216 | 340 | MT4 | 10(5+5) |

| 45.0 | 〃 | 95 | 216 | 340 | MT4 | 10(5+5) |

| 46.0 | 〃 | 95 | 216 | 340 | MT4 | 10(5+5) |

| 47.0 | 〃 | 95 | 216 | 340 | MT4 | 10(5+5) |

| 48.0 | 〃 | 100 | 226 | 350 | MT4 | 10(5+5) |

| 49.0 | 〃 | 100 | 226 | 350 | MT4 | 10(5+5) |

| 50.0 | +0.024 +0.011 |

105 | 239 | 385 | MT5 | 12(6+6) |

| 51.0 | 〃 | 105 | 239 | 385 | MT5 | 12(6+6) |

| 52.0 | 〃 | 105 | 239 | 385 | MT5 | 12(6+6) |

| 53.0 | 〃 | 105 | 239 | 385 | MT5 | 12(6+6) |

| 54.0 | 〃 | 105 | 239 | 385 | MT5 | 12(6+6) |

| 55.0 | 〃 | 105 | 239 | 385 | MT5 | 12(6+6) |

| 56.0 | 〃 | 105 | 239 | 385 | MT5 | 12(6+6) |

| 57.0 | 〃 | 105 | 239 | 385 | MT5 | 12(6+6) |

| 58.0 | 〃 | 105 | 239 | 385 | MT5 | 12(6+6) |

| 59.0 | 〃 | 105 | 239 | 385 | MT5 | 12(6+6) |

| 60.0 | 〃 | 105 | 239 | 385 | MT5 | 12(6+6) |

| 61.0 | 〃 | 105 | 239 | 385 | MT5 | 14(6+8) |

| 62.0 | 〃 | 105 | 239 | 385 | MT5 | 14(6+8) |

| 63.0 | 〃 | 115 | 249 | 405 | MT5 | 14(6+8) |

| 64.0 | 〃 | 115 | 249 | 405 | MT5 | 14(6+8) |

| 65.0 | 〃 | 115 | 249 | 405 | MT5 | 14(6+8) |

| 66.0 | 〃 | 115 | 249 | 405 | MT5 | 14(6+8) |

| 67.0 | 〃 | 115 | 249 | 405 | MT5 | 14(6+8) |

| 68.0 | 〃 | 115 | 249 | 405 | MT5 | 14(6+8) |

| 69.0 | 〃 | 115 | 249 | 405 | MT5 | 14(6+8) |

| 70.0 | 〃 | 115 | 249 | 405 | MT5 | 14(6+8) |

New stacking

(Cobalt High SKH 40) S-axis specification

[3 mm to 14 mm - 0.05 mm jump standard item], [3 mm to 32 mm - 0.1 mm jump standard item], [3 mm to 50 mm - 0.5 mm jump standard item]

| OD | tolerance | Blade length | Shank diameter | Shank length | full length | Number of blades

(Boring / cutting edge) |

|---|---|---|---|---|---|---|

| 3.0 | +0.009 +0.004 |

25 | 4.0 | 25 | 70 | 4(2+2) |

| 3.5 | 〃 | 25 | 4.0 | 25 | 70 | 4(2+2) |

| 4.0 | 〃 | 30 | 5.0 | 25 | 75 | 4(2+2) |

| 4.5 | 〃 | 30 | 5.0 | 25 | 75 | 4(2+2) |

| 5.0 | 〃 | 30 | 6.0 | 30 | 85 | 4(2+2) |

| 6.0 | 〃 | 30 | 6.0 | 30 | 90 | 4(2+2) |

| 7.0 | +0.012 +0.006 |

35 | 8.0 | 35 | 100 | 4(2+2) |

| 8.0 | 〃 | 40 | 8.0 | 40 | 120 | 4(2+2) |

| 9.0 | 〃 | 40 | 10.0 | 40 | 130 | 4(2+2) |

| 10.0 | 〃 | 48 | 10.0 | 45 | 140 | 6(3+3) |

| 11.0 | +0.015 +0.007 |

48 | 10.0 | 45 | 150 | 6(3+3) |

| 12.0 | 〃 | 54 | 12.0 | 45 | 155 | 6(3+3) |

| 13.0 | 〃 | 54 | 12.0 | 50 | 160 | 6(3+3) |

| 14.0 | 〃 | 57 | 12.0 | 50 | 170 | 6(3+3) |

| 15.0 | 〃 | 60 | 12.0 | 105 | 180 | 6(3+3) |

| 16.0 | 〃 | 60 | 16.0 | 105 | 180 | 6(3+3) |

| 17.0 | 〃 | 65 | 16.0 | 110 | 190 | 6(3+3) |

| 18.0 | 〃 | 65 | 16.0 | 110 | 190 | 6(3+3) |

| 19.0 | 〃 | 70 | 16.0 | 115 | 200 | 6(3+3) |

| 20.0 | 〃 | 70 | 16.0 | 115 | 200 | 6(3+3) |

| 21.0 | 〃 | 70 | 20.0 | 135 | 220 | 6(3+3) |

| 22.0 | 〃 | 75 | 20.0 | 130 | 220 | 6(3+3) |

| 23.0 | 〃 | 75 | 20.0 | 140 | 230 | 6(3+3) |

| 24.0 | 〃 | 75 | 20.0 | 140 | 230 | 8(4+4) |

| 25.0 | 〃 | 75 | 20.0 | 140 | 230 | 8(4+4) |

| 26.0 | 〃 | 80 | 25.0 | 155 | 250 | 8(4+4) |

| 27.0 | 〃 | 80 | 25.0 | 155 | 250 | 8(4+4) |

| 28.0 | 〃 | 80 | 25.0 | 155 | 250 | 8(4+4) |

| 29.0 | 〃 | 80 | 25.0 | 155 | 250 | 8(4+4) |

| 30.0 | +0.020 +0.009 |

85 | 25.0 | 170 | 270 | 8(4+4) |

| 31.0 | 〃 | 85 | 25.0 | 170 | 270 | 8(4+4) |

| 32.0 | 〃 | 85 | 25.0 | 170 | 270 | 8(4+4) |

| 33.0 | 〃 | 90 | 25.0 | 195 | 300 | 8(4+4) |

| OD | tolerance | Blade length | Shank diameter | Shank length | full length | Number of blades

(Boring / cutting edge) |

|---|---|---|---|---|---|---|

| 34.0 | +0.020 +0.009 |

90 | 32.0 | 195 | 300 | 8(4+4) |

| 35.0 | 〃 | 90 | 32.0 | 195 | 300 | 10(4+6) |

| 36.0 | 〃 | 90 | 32.0 | 195 | 300 | 10(4+6) |

| 37.0 | 〃 | 90 | 32.0 | 195 | 300 | 10(4+6) |

| 38.0 | 〃 | 90 | 32.0 | 195 | 300 | 10(4+6) |

| 39.0 | 〃 | 90 | 32.0 | 195 | 300 | 10(4+6) |

| 40.0 | 〃 | 100 | 32.0 | 210 | 330 | 10(4+6) |

| 41.0 | 〃 | 100 | 32.0 | 210 | 330 | 10(4+6) |

| 42.0 | 〃 | 100 | 32.0 | 210 | 330 | 10(4+6) |

| 43.0 | 〃 | 100 | 32.0 | 210 | 330 | 10(4+6) |

| 44.0 | 〃 | 100 | 32.0 | 210 | 330 | 10(4+6) |

| 45.0 | 〃 | 100 | 42.0 | 230 | 360 | 10(4+6) |

| 46.0 | 〃 | 100 | 42.0 | 230 | 350 | 10(4+6) |

| 47.0 | 〃 | 100 | 42.0 | 230 | 350 | 10(4+6) |

| 48.0 | 〃 | 100 | 42.0 | 230 | 350 | 10(4+6) |

| 49.0 | 〃 | 100 | 42.0 | 230 | 350 | 10(4+6) |

| 50.0 | +0.024 +0.011 |

110 | 42.0 | 240 | 370 | 12(6+6) |

| 51.0 | 〃 | 110 | 42.0 | 240 | 370 | 12(6+6) |

| 52.0 | 〃 | 110 | 42.0 | 240 | 370 | 12(6+6) |

| 53.0 | 〃 | 110 | 42.0 | 240 | 370 | 12(6+6) |

| 54.0 | 〃 | 110 | 42.0 | 240 | 370 | 12(6+6) |

| 55.0 | 〃 | 110 | 42.0 | 240 | 370 | 12(6+6) |

| 56.0 | 〃 | 110 | 42.0 | 240 | 370 | 12(6+6) |

| 57.0 | 〃 | 110 | 42.0 | 240 | 370 | 12(6+6) |

| 58.0 | 〃 | 110 | 42.0 | 240 | 370 | 12(6+6) |

| 59.0 | 〃 | 110 | 42.0 | 240 | 370 | 12(6+6) |

| 60.0 | 〃 | 110 | 42.0 | 240 | 370 | 12(6+6) |

Please purchase the product at a machine tool trading company